DIGITAL FABRICATION

Medical Mask

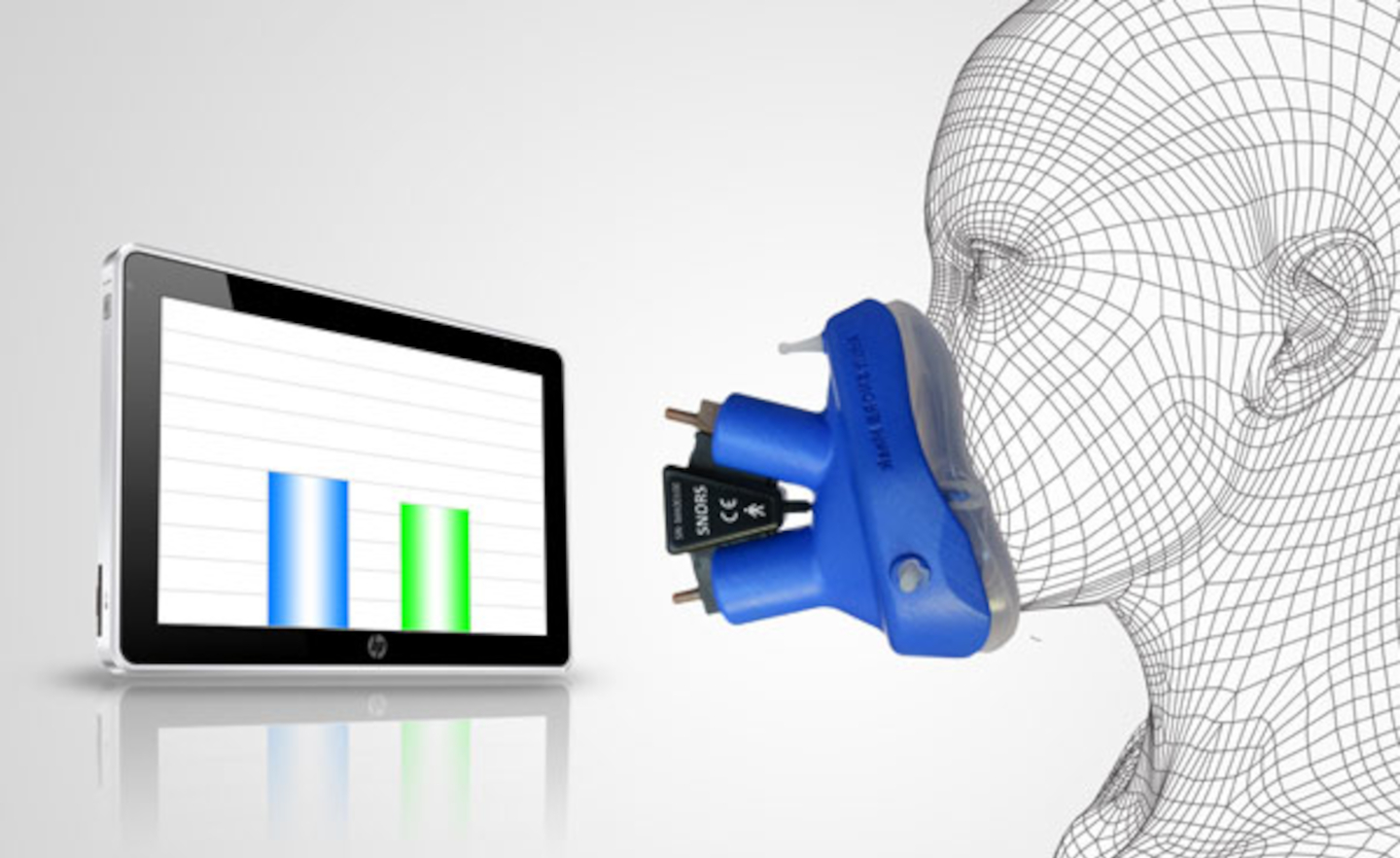

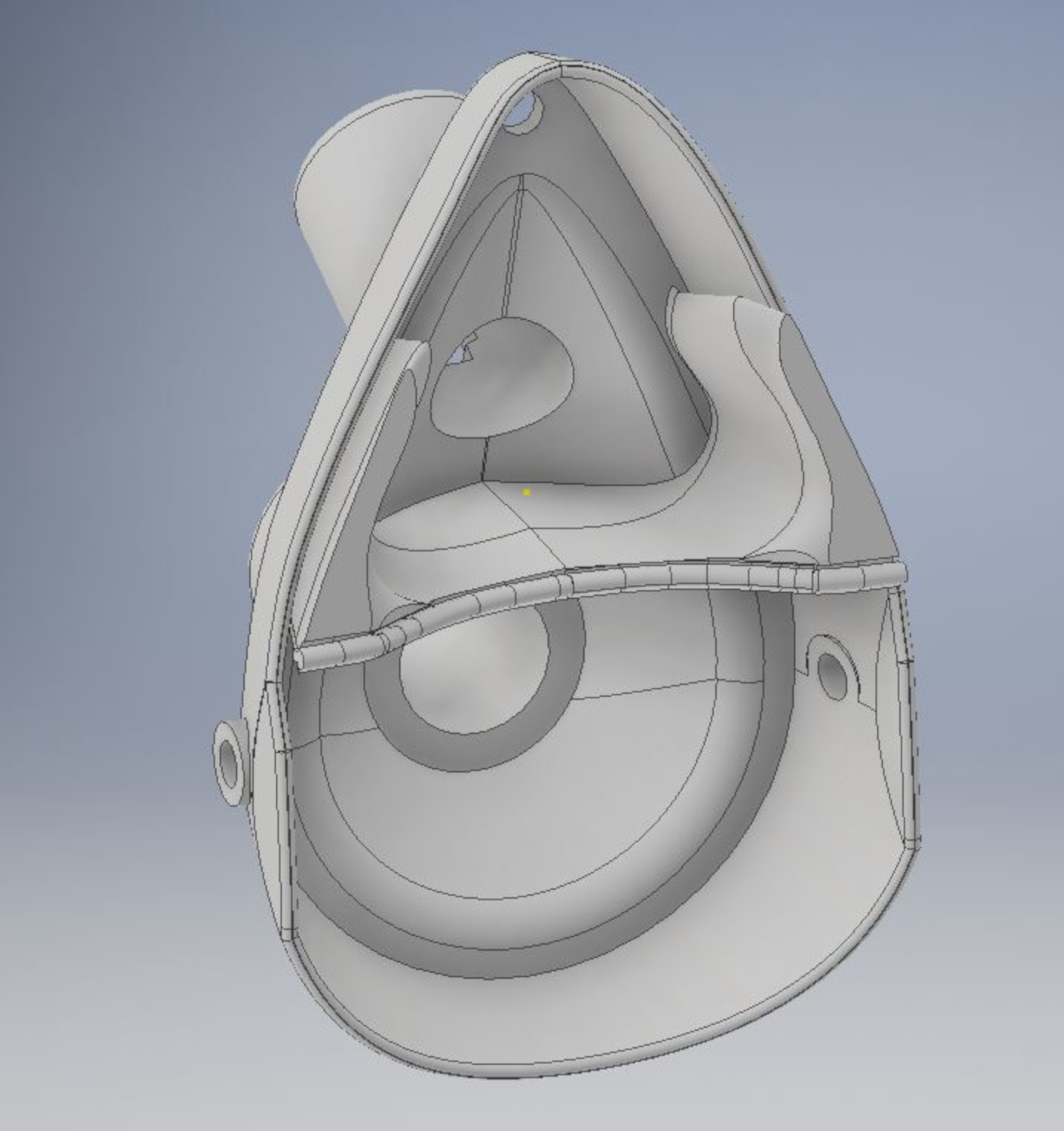

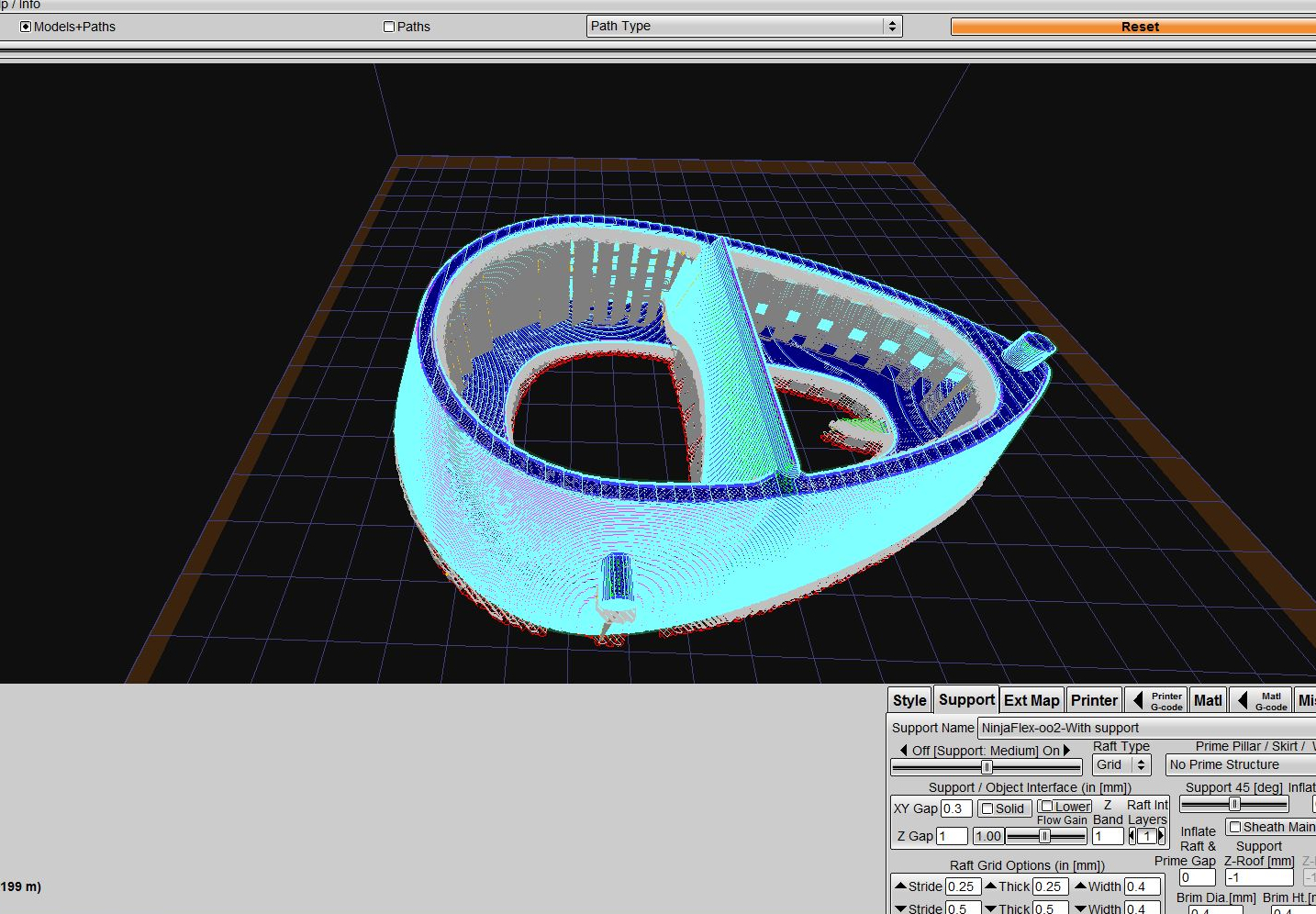

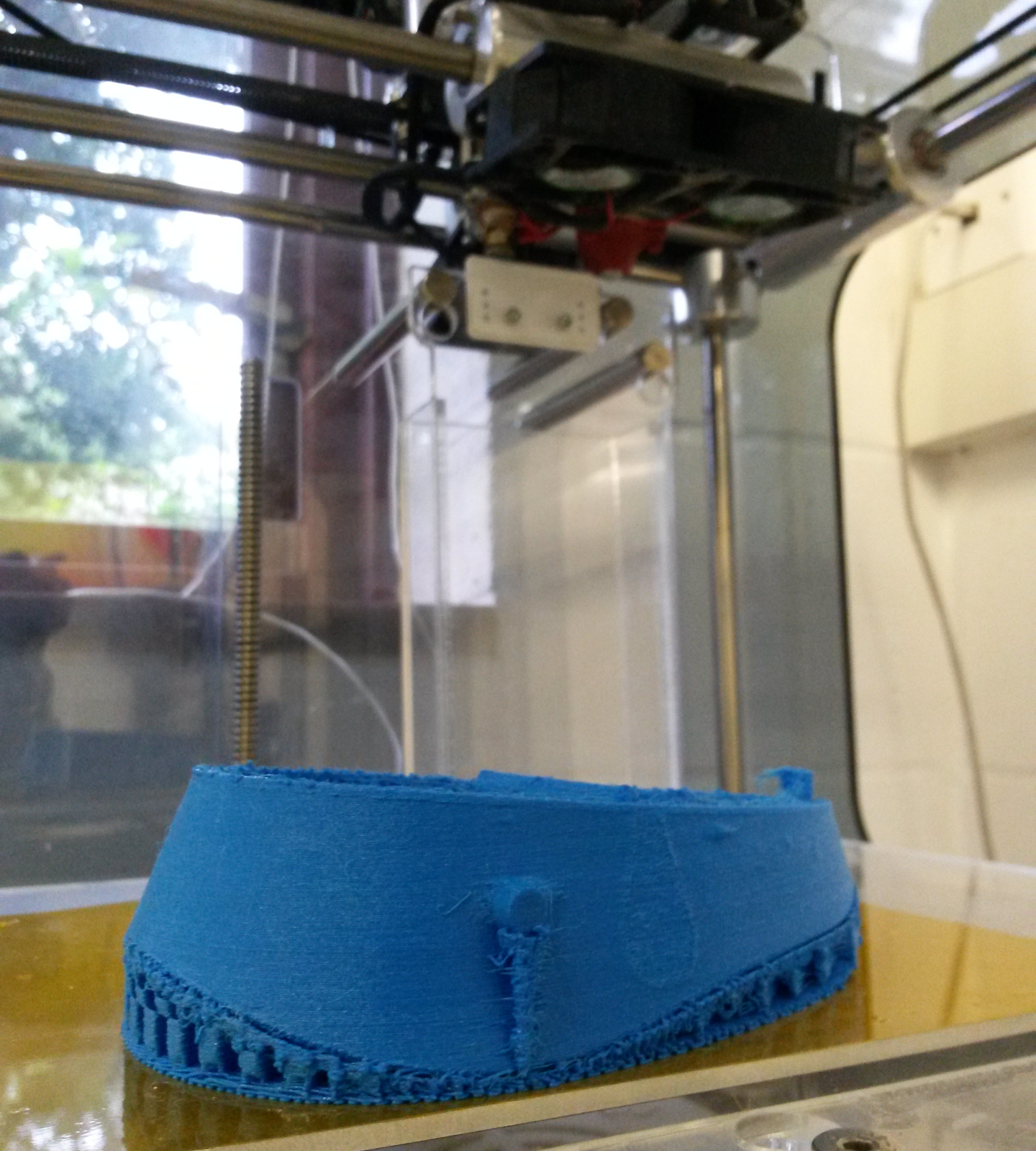

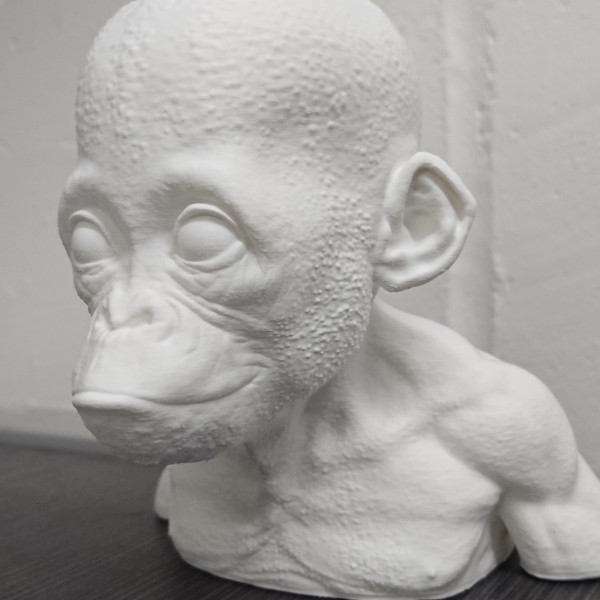

I was approached by Dr Paul Sharp, Technical Director of Rose Medical Solutions in regards to a multi-parameter speech workstation designed specifically for clinical use. The device enabled a process of speech analysis on adults and children, through the use of a physical object to attain data, and a software, developed by Dr Sharp, to analyse the data. The initial brief was to convert the analogue method of creating the SNORS (Super Nasal-Oral Ratiometry System) mask into a digital format, which then further developed into a product development exercise on a digital platform to enable experimentation through 3D prototyping to achieve the best possible outcome result. The work undertaken for Dr Paul Sharp was based on a workflow that incorporated 3D scanning, 3D modelling and 3D printing.Dr Paul Sharp stated “Due to the specialised nature of our products, it is not always cost-effective to use mass production techniques such as injection moulding. Working with the Kent School of Architecture at the University of Kent enabled our small electronics company to utilise 3D printing technology to create low volume medical devices. Julien Soosaipillai first introduced us to the concepts of 3D printing and guided us through the different printing techniques and materials. His expertise and patience enabled us to go from proof of concept to product in an extremely short timeframe. The technology will be used worldwide to provide a non-invasive assessment of hyper nasal speech in children with cleft palate.”

Client

Dr Paul Sharp

Role

Technical Specialist at UKC

Date

Aug 2016

Application

Fusion360, KISSlicer